Pressure Balanced Expansion Joints

Product Overview

PRESSURE BALANCED EXPANSION JOINTS

Pressure balanced expansion joints are designed to absorb movements from a pipe system. They can accommodate axial and lateral movements where anchoring of the pipe system is difficult or impractical due to structural or economic considerations. Pressure balanced expansion joints do not transfer the internal pressure thrust on to the fix points, adjacent equipment, or structures. Fix points are usually not required, only guides can ensure the turning of thermal expansion into a controlled movement.

Therefore, pressure balanced expansion joints can offer significant advantages, where pipe systems are connected with turbines, pumps, valves or other equipment, that are unable to withstand pressure thrust loads.

- In-line pressure balanced pipe expansion joints

- Elbow Pressure Balanced Pipe Expansion Joint

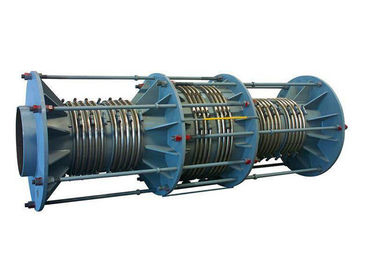

In-line pressure balanced pipe expansion joints

The in-line pressure balanced Expansion Joint is designed to absorb axial movement and/or lateral deflection while restraining the pressure thrust by means of tie devices interconnecting the line bellows with outboard compensating bellows also subjected to line pressure.

Each bellows set is designed to absorb the axial movement and usually the line bellows will absorb the lateral deflection. This type of Expansion Joint is used in a straight run of piping.

Dewdon in-line pressure balanced pipe expansion joint is an effective solution to combatting intricate design problems. The key to this type of unit is the same as our pressure-balanced elbow type wherein axial thrust is reacted upon by the contraction acting on a cross-sectional range equal to the area of the working or primary bellows.

Features

- Ease of production

- High-pressure resistance

- Absorbs small amounts of axial and lateral movement

- Eliminates compression

- No main anchors required

- Conserves space

Elbow pressure balanced pipe expansion joint

The Elbow pressure balanced expansion joints or corner relief expansion joints are the types of pressure balanced expansion joints, which are used where pressure thrust forces on equipment or piping is unacceptable and the direction of the pipe system also changes.

This elbow pressure balanced pipe expansion joint is really a combination of several types. Its purpose is to retain and balance the pressure thrust so that main anchoring of the pipe or adjacent equipment is not required, and forces and movements on attachment flanges of delicate equipment, such as turbines, are kept to acceptably low levels. The deflections to be accepted are handled by the proper type of pipe expansion joint, which normally, is a tied universal type to accept lateral movements. However, the pressure balanced elbow is usually required because axial deflections are also present.

Features

- Absorbs axial and lateral movements

- Eliminates main anchors

- Minimum guiding required

- Pressure forces remain in balance

- No volume change

- Balance-pressure thrust remains constant

Externally pressurised type expansion joints

Dewdon is the leading producer of domestically manufactured Externally Pressurized expansion joints and is proud to have been the selected vendor for one of the world’s largest district steam system distributors.

Dewdon’s Externally pressurised type expansion joints is the perfect solution when axial movements and pressure is high.

Bellows elements of externally pressurised expansion joints are arranged so that the media flow is on the external side of the bellows, while the inside part of the bellows is only subjected to atmospheric pressure with this side being in direct connection with the atmosphere.

Features

- Externally pressurized expansion joints are used if there would be large axial movements.

- This type of expansion joint pressurizes the bellows externally, eliminating column instability concerns for the bellows.

- This configuration provides an outside cover protecting bellows from external elements and inside pipe acts as a liner protecting bellows from flow medium and and streamlines the flow.

- Minimizing pressure losses

Application

- Hot & Cold Water

- Superheated water,

- Steam and condensate pipelines

- Industrial Applications

- HVAC lines

- In large plants with thermal equilibrium and mechanical expansion

- Geothermal plants

- Integrated city district heating

- The widest application area is underground pipe lines.

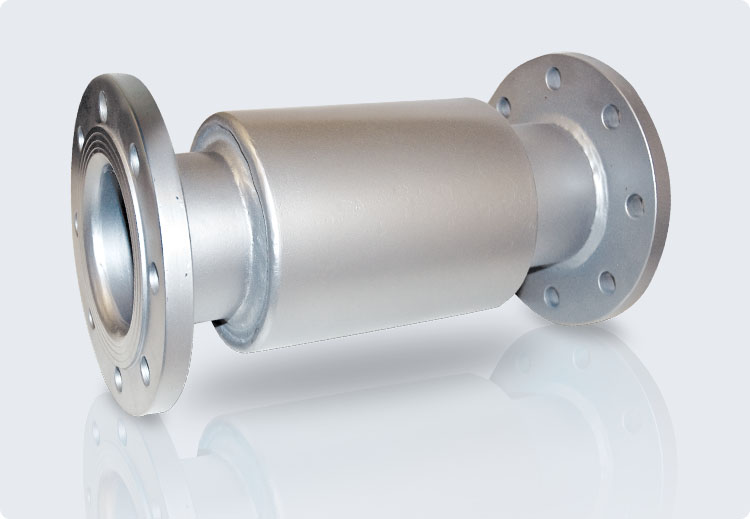

High pressure metal expansion joint

High Pressure type Metal Expansion Joint is used in cases of high internal pressures and/or equalizing the movement among all the corrugations.

The High Pressure Metal Expansion Joint is composed of a single bellow of several waves in the form of “U”. These waves are made by one or more metal sheets longitudinally welded and shaped hydraulically or mechanically.

The main mission of the High Pressure Metal Expansion Joint is to absorb axial expansion movements both thermal and mechanical origin under high pressure conditions.

The system involves the use of reinforcement or equalizing rings located around the outside of the convolution thus preventing the bellows being forced out of shape due to the high pressures.

Equalizing and Reinforcing Rings are devices used on some expansion joints fitting snugly in the roots of the convolutions. The primary purpose of these devices is to reinforce the bellows against internal pressure and equalize the movement among all the corrugations.

Equalizing and reinforcing rings are made of carbon steel, stainless steel or other suitable alloys.

Features

- High temperature resistance, water and chemical corrosion resistance.

- High flexibility, high fatigue life, compact structure, reliable sealing and other features.