Spool Type

Product Overview

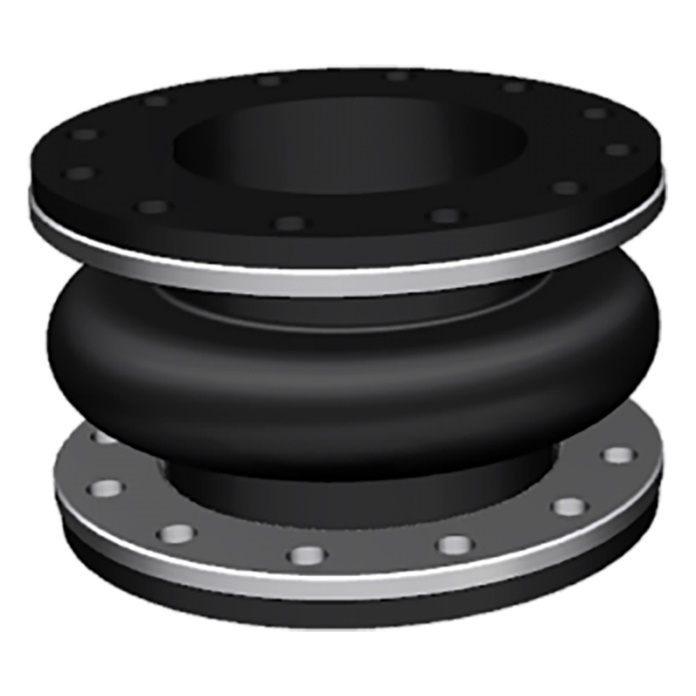

SPOOL TYPE

Spool type rubber expansion joints have the same function as mould pressing type rubber expansion joints, used in metal pipe systems for vibration isolation, reducing noise, and displacement compensation. A spool-type expansion joint is the most common type with flanged ends.

Spool-type joints derive their radial strength from wire or steel ring reinforcement. The only part of the joint that is not rigidly reinforced is the arch itself. Since the design is for industrial applications where noise and vibration are of little consequence, spool-type expansion joints only address movements. The arch is very heavily reinforced and quite stiff as well, so there is little change in volume in response to pressure.

Features

- Flexible structure, it can satisfy different installation length and different flange connection dimension requirements.

- Hand-built construction.

- Single to multiple arches available.

- Variety of retaining ring material and applied flange Code.

- Internal sleeve or protective cover available.

- Reinforcement / spiral steel wire or steel bar as required.

- Wide range of product size, NPS 2 thru 176 inch.

High pressure bearing effect. Since spool type rubber expansion joints are not limited by mould size, its skeleton layers is 2-4 couples more than mould pressing products, therefore, it has higher pressure bearing capacity, when come across negative pressure, we can add negative pressure resistant steel wire or made inner wall into straight tube shape to meet using requirements.